Rosenberg

Rosenberg 230V Unobox-ME exhaust air boxes AC

Rosenberg 230V Unobox-ME exhaust air boxes AC

Couldn't load pickup availability

for higher conveying temperatures and washable.

properties and designs

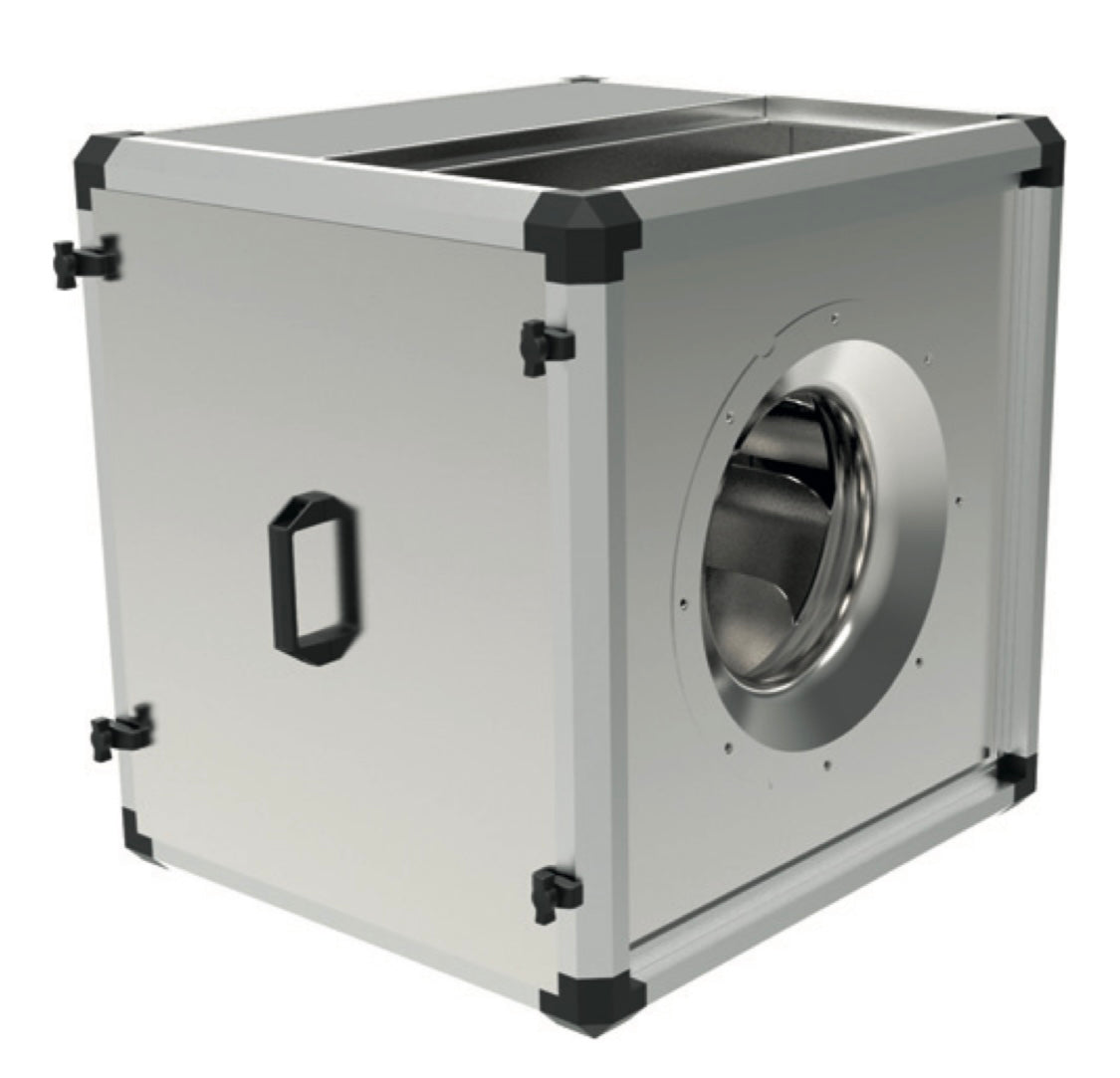

The flexible and compact Unoboxes are designed to convey small to medium volume flows. The Unobox-ME is suitable for use in kitchen exhaust air in accordance with VDI 2052. A removable maintenance door, an integrated drip tray with condensate drain nozzle (LOSE, 3/4") and special sealing lips are also part of the delivery standard, as is the motor arranged outside the air flow. Insulating nozzles must be used as duct connectors for kitchen exhaust air. The housing consists of a housing frame made of two-chamber aluminum profiles and plastic corners, as well as double-shell, 20 mm thick panels made of galvanized sheet steel with insulation made of non-flammable, sound and heat-insulating glass wool mats. The air direction can be changed at any time at the installation site. This flexibility ensures maximum adaptation options to the structural conditions. Outdoor installation is possible with accessories such as a rain cover, blow-out hood, etc. All plastic parts and cables are UV-resistant. Backward-curved high-performance impellers made of aluminum are used. Up to size 500, the drive is via an external rotor motor with an extended shaft. From size 560, IEC standard motors are used.

air performance characteristics

The characteristic curves for these series were recorded in accordance with DIN EN ISO 5801 in installation type A (free suction and connected on the pressure side) and show the pressure increase Δ pfa available on the suction side as a function of the volume flow.

noises

The A-weighted free-discharge sound power level L WA6 is specified in the air performance curves (numbers in a border). The A-weighted free-intake sound power level L WA5 and the housing radiation sound power level L WA2 (sound measurement carried out in accordance with DIN EN ISO 3745 and ISO 13347-3 using the envelope method) are calculated using the formula to the right of the air performance curve. The A-weighted sound pressure level L pA at a distance of 1 m can be approximately obtained by subtracting 7 dB(A) from the A sound power level. It should be noted that reflections and room characteristics, as well as natural frequencies, influence the size of the sound pressure level differently. The relative octave sound power levels L WArel at the octave center frequencies can be taken from the directly assigned tables of the respective fan types.

Catalog (from page 178): https://www.rosenberg-gmbh.com/de/component/phocadownload/category/12-ventilatoren?download=238:katalog-ac-ventilatorenwelt

Share